by Dave Lawler in the May 1979 RootesReview

While having some discussions about maintaining oil pressure in a racing configured engine it became apparent to me that many people may be missing a serious problem. As a result of many forages to junk yards looking for parts I always remove the pressure regulator in what is left of engines – hoping to find a good one. Usually they are jammed, broken or crunched in some way. This is usually the prime reason the car is there the failure of this component usually results in spun bearings, thrown rods or similar disasters. The failure is rarely without warning or indication – if you can interpret the signs.

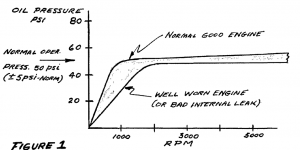

The basic theory of operation is that the oil pump delivers oil at an approximately linear rate with engine RPM. In order to maintain constant pressure at RPM levels above idle, the regulator senses the pressure and bypasses excess oil back to the sump, resulting in an essentially constant pressure. Figure 1 illustrates the approximate pressure/RPM relationship of a correctly operating system.

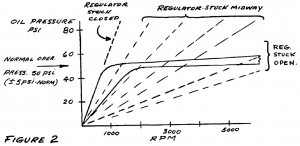

The initial failure mode is usually a sticking of the regulator in one of many positions. I’ve found that it sticks usually on initial startup and towards the full open position. How far open is dependent on temperature. In most cases it appears to be caused by a build-up of varnish or sludge. I’ve a hard time understanding how it happens in an immaculately clean engine but it does. Some of this may be explained by the fact that the regulator is located before the oil filter, and the tolerances of the moving parts are extremely tight. The operating characteristics of a sticking regulator are shown in figure 2.

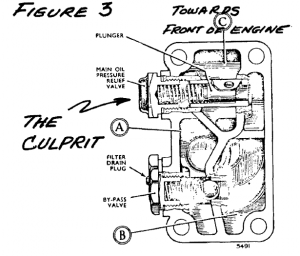

The cure, although always temporary, is to remove the 13/16 nut assembly to which the regulator operating portions are soldered. Clean by immersing in a solvent. Use a WOODEN STICK – NOT METAL to move the core of the regulator in and out until perfectly free. If you scratch the internal wall of the regulator you’ll have more trouble. A section of the base assembly is shown in figure 3.

I’ve found if it sticks while on the road with no tools you can, in a good engine, keep the pressure up to above 20 psi (very marginal), with high RPM and low gearing, enough to get to a service station. However, after a couple of these experiences I carry a 13/16 socket, a wooden stick and a baby food jar with solvent as my primary emergency tool kit Someday {when I get aggravated enough) I’ll get around to designing a poppet regulator which would not suffer from this problem. In the meantime keep at least one eye on your gauge.

I’ve found if it sticks while on the road with no tools you can, in a good engine, keep the pressure up to above 20 psi (very marginal), with high RPM and low gearing, enough to get to a service station. However, after a couple of these experiences I carry a 13/16 socket, a wooden stick and a baby food jar with solvent as my primary emergency tool kit Someday {when I get aggravated enough) I’ll get around to designing a poppet regulator which would not suffer from this problem. In the meantime keep at least one eye on your gauge.

(Ed Note: also refer to tips C2 and C15 on this subject.)

Comments (1)

Dave ha a great method of working with the problem of sticking oil pressure relief valves. Also, the factory was aware of the problem with Series IV & V engines. There was a factory service bulletin on dealing with the problem. The bulletin was published in the news letters Tech Tips in the late 70s or early 80s. If memory serves is said to replace the unit with one from a Series 1-2-3 engine. Good luck with that now. The problem was such that I never saw a Series IV/V with more than 70k miles. A contemporary fix may be found by machining the bore for a stainless steel sleeve (polished) and the piston Teflon-boron plated and the pair match fitted with the clearances set at engine oil operating temperature. Once this is done the use of synthetic oil would be recommended. This should be done only with an engine that is super clean internally. *)