Words and photos by Bill Rogers

Download a January 2021 updated and large pdf of this article

PDFs open in new windows. Most images will display at full size upon click.

What’s in a complete set of tools for a Sunbeam Tiger?

As the price of Tigers has increased, more and more are appearing from barns, sheds, and from beneath piles of junk in the back of garages to be restored and flipped for a profit. The best ones from our well-known restorers are better than when they rolled off the Jensen line. If you are one of the people that drives your car, fine, but if you are interested in a concourse machine, the car must be as close to the original production car as possible. That means complete with the tools as delivered. Unfortunately many original owners back in the day kept the tool kit when they sold the car. Those tools disappeared into the bottom of a tool box, separated forever from their original home in the trunk.

Prior Bibliography

There have been several articles about the tools published in the past: Norm Miller’s “The Book of Norman” does not give many details. It covers the trunk components in a short paragraph (P 154) and includes a black and white photograph of a Mk II tool kit (P 175).

Mark Olsen wrote a more definitive piece which is available on the Tigers United website. He also provided a version of that article to STOC (the Brit Tiger Club) for their magazine, Cats Whiskers. For some time it was viewable on their website but it has since been removed.

Classic Tiger (Mark Olsen’s own site) has a listing with clickable images that are better than those on Tigers United. It is likely that the CAT (LA Tiger Club), STOA (Bay Area Tiger Club) or TE/AE (Eastern US Club) will have had articles in their magazines in Tech Tips over the years.

Contemporary Documents

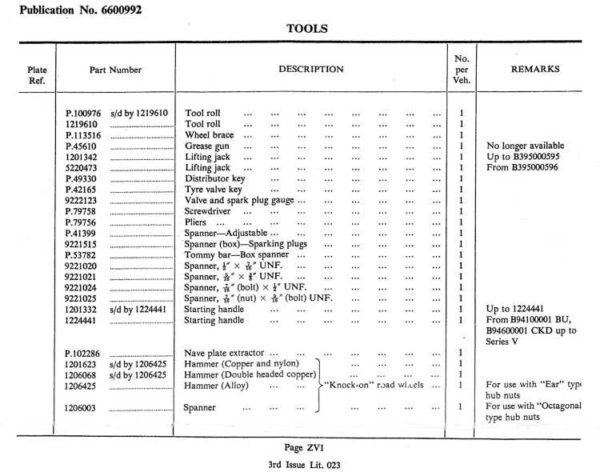

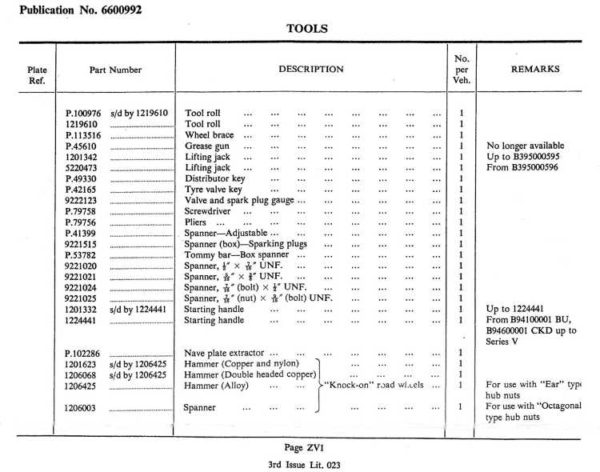

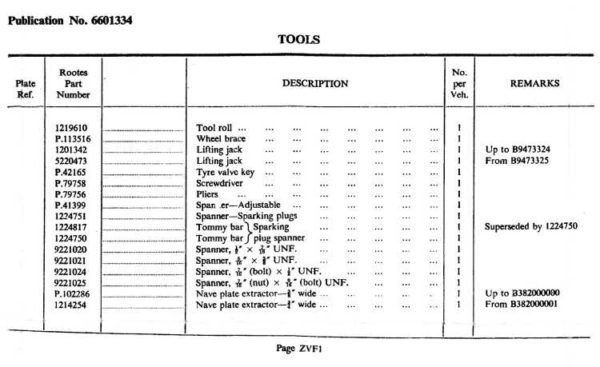

These are usually more reliable than 50-year-old memories and the first three illustrations are the Rootes Parts List entries for the tool kits. The Alpine list is first and the Tiger lists (Alpine 260 and Alpine 260, 289) that follow were supplements to the Alpine list.

Caveat: My research is based on two cars, widely separated in the production run and it is statistically invalid to extrapolate from a very small sample size to a population of about 7,000 Tigers. A larger sample would have validated the information presented here. Dave McDermott, owner of the Targa Florio Tiger, has done extensive research on tool kits. His review of this article:

For what it is worth I closely examined the tool kits in 2 different cars that were owned locally from new and they corroborate what is in the article.

One of those was a late MK II and did indeed have the extra oil cooler spanner. However just because a few cars had the same exact tools does not necessarily mean that all cars in between had the same exact tools.

We don’t know the ordering process used at Rootes to know whether they ordered parts from suppliers in batches of 1,000, 2,000 or all 7,000. If as I suspect in smaller batches then there could be some minor differences and if in smaller batches then were they just dumped into the parts bin on top of the remaining stock? However with the consistency we have found so far it probably is safe to make the assumption that all the tool kits were identical except for extremely minor differences.

Given the fact that part numbers were unchanged except for the Jack, Nave Plate Remover and Tommy Bar, and we checked 4 cars, it is fairly safe to assume that we are on the right track.

If you compare this with the following Tiger lists, you can see that many items were common with the Tiger. We have good examples here of Brit vs American terminology; to reduce confusion I have used Brit terminology – Americans can refer to the dictionary below. You will notice that some parts have 7-digit numbers which indicates that they probably had Humber- Hillman (Rootes drawing office) numbered drawings. I have not been able to find any of these drawings (except for the Tool Roll above) in searches of the Rootes archive drawings and microfiche. I think the other numbers with P prefixes are part numbers from outside suppliers.

Many items are not common with the Tiger such as Starting Handles and Hammers for knock-on wheels, however for future reference take note of the item with part # P.49330 the Distributor Key.

From the Tiger lists you can see that during production, the tool kit contents changed. The Lifting Jack was lengthened and installed first on B9473325. This necessitated a rearrangement of the clips holding the jack and wheel brace in place in the RHS of the trunk floor. The Tommy Bar was changed ( I have not discovered in what way) and the first Mk 1A had the 3/4″ wide Nave Plate Extractor in place of the more complicated 3/8″ wide item found with the Mk 1.

You will notice that the notation for the spanners describes the nuts and bolts that they fit, rather than the AF (Across Flats) designation that appears on the wrenches themselves. This allows you to compare nut and bolt sizes with the equivalent AF dimension. Find a 12 page cross reference here. It’s very big pdf file that opens in a new window.

By all accounts the Mk II had one additional spanner for the oil cooler, but that does not appear in the parts list for some reason.

Note that there is no reference anywhere to the Lucas Distributor Key, but the Tire Valve Key is listed.

Most of the following information and illustrations for this article are from two cars that have been in the family from new

The Mk 1 was built in Feb 1965 and sold as new in 1966; I became its custodian in 1978. It was unmolested when I began work on it and the tool set was complete except for the Tire Valve Key and Lucas Points Tool. The original purchaser did not remember either part coming with the car.

The Mk 1A was built in May of 1966 and purchased in that year. Although the car is personalized, it retains all the tools that it came with. The original owner assured me that the tool roll contained the Lucas Points Tool but could not remember the tire valve tool being present.

These two cars with similar kits cover about half of Tiger production, and it would be interesting to compare them with original earlier and later cars.

Options for replacement parts are listed below.

Jack

It is generally accepted that the jacks used on the Tiger were manufactured by Shelly in Birmingham.

An interesting website covers these jacks and the information on the two lengths matches the information above, except it states that Tiger II jacks were painted gray. Norm Miller and other authorities contend that jacks for the Mk II were black like the earlier cars.

There has been discussion about the Shelly sticker that was apparently attached about an inch above the arm that is inserted into the sockets under the bumpers. Several unmolested jacks have been examined and show signs of residual dried up adhesive; apparently the glue did not hold up well and the stickers fell off. Reproductions of these stickers are available on Ebay.

Some jacks have feet that are more convex like the one shown at the left, rather than the flattish ones shown above. I do not know if these were used on the Tiger.

The Tool Roll

The tool roll is stowed in the left rear corner of the trunk and secured with a black fabric strap, which is clamped and riveted to the trunk floor with the buckle to the rear. The tool roll itself is a flimsy black vinyl piece with pockets, secured with a piece of greyish black fabric tape heat welded to the roll. This tape seems to fade to tan over time.

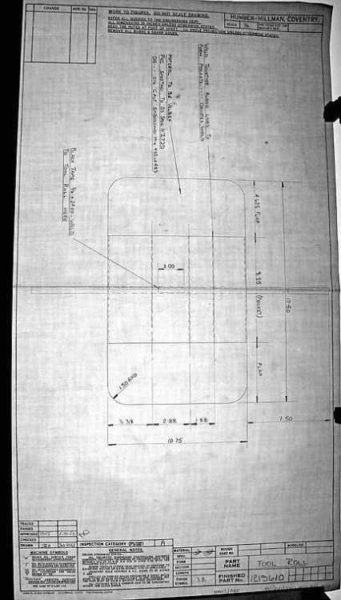

If someone should wish to reproduce this item, the center piece is about 2 ½” longer than the basic outer cover width of 10.75″ to allow for the pockets. Other dimensions are on the drawing shown at the top of the page.

Tool Roll Contents

Spanners

The Mk 1 and Mk 1A came with four TW “Superslim” spanners in the following AF (Across Flat) sizes.

7/16 AF X 1/ 2 AF

9/16 AF X 1/ 2 AF

3/4 AF X 5/8 AF

11/16 AF X 13/16 AF

The Mk II had one additional 15/16 AF X 7/8 AF to fit the oil cooler that looks similar.

The Spanners have “Made In England” and the TW logo on one side and the “Superslim” trade mark on the other. The ends have the AF sizes on both sides – no BSF or Whitworth! Finish is an oil baked black color.

Some have various small letters and numbers as well, but these are not consistent and an artifact of the manufacturing process, perhaps to track forging tool wear.

T. Williams spanners were made in Birmingham and were supplied to many British car manufacturers for tool kits.

Pliers

Pliers have “Made in Sheffield England” in small shallow letters around the pivot, which are sometimes almost obscured by the coating, no wire cut slots and a round hole. The finish is similar to the spanners.

Screwdriver

The Screwdriver is a little over ten inches long with a wood handle, tapered metal sleeve, and a round shanked, dark metal blade. The wooden ball is not round but flatter on two sides.

King Dick Adjustable Spanner

This little-over-four-inch-long version of the King Dick Adjustable has the name stamped on the slide. Dark metal color.

Nave Plate Extractor

The Extractor is shaped sheet metal with normal dark coloring. A 3/8″ wide item with less than 90 degree bend and a subtle shape was used on the Mk1, while the Mk1A and Mk II use a 3/4″ wide, flat tool with a 90 degree bend.

Tire Valve Tool

This yellow plastic device is about 3/16 in diameter and easily lost!

Tommy Bar and Sparking Plug Spanner

These item are unique to the Tiger and thus very rare. They have a dull black metal finish like the other items, except the shiny silver ball detents at the end of the Tommy Bar. Both items have stamped part numbers as indicated in the photos; Z5798 and Z5799. The spring-loaded ball detents fit into a machined groove inside the Spanner. Note the distortion created as the bar was bent.

Lucas Distributor Key

I have left this to last since it is not listed in the Rootes Tiger documents, only the Alpine list. Other authorities and some owners insist that the item was delivered with the car. It is stamped .014 .016 Lucas. According to Mark Olsen, the Lucas P/N is 400935 RD 5 4.

Remaining Questions

- The Tommy Bar P/N 122 4817 was replaced by P/N 122 4750. Since the Alpine 260 Parts List gives the 4817 number for the Mk1 and the Mk 1A, and the two kit that I checked had an identical part, the change over must have occurred subsequent to B382002035. This would happen at no fixed cut-in point since the car itself was not changed. The jack change required repositioning of the mounting clips in the trunk and thus had a fixed cut-in point.

What is the difference between the two part numbers? If someone has a later car with an original tool kit, perhaps they can compare their Tommy Bar with the photograph.

- The Lucas Distributor Key measures a points gap of .014 – .016 but per the workshop manual the 260 distributor requires a gap of .015″. It appears the tool would be useful as a go – no go gauge, even though the distributor was a Ford-supplied part. The Mk II points gap should be .017″.

Why were some cars delivered with an Alpine tool? Perhaps the same person assembled Tiger and Alpine kits and just threw them in from a stock pile.

- Why was the additional MkII spanner not included in the parts list?

Probably Publications had not caught up with MkII production when development was cancelled.

Parts Availability

I was given an original plastic tool roll in excellent condition and decided to try to reconstruct an authentic tool kit as part of this 2017 project. The wheel brace, lifting jack, screwdriver, pliers, spanners and nave plate tool are common with the Alpine, thus more readily available since over 100K were made. We have not tried to source the Jack and Wheel Brace since these generally stayed with the cars, and are often available.

Plastic Tool Roll: Original tool rolls are fragile and most were discarded, so they are extremely rare in good condition. I have seen very few of these for sale and our best bet is to have someone reproduce it.

Spanners: The spanners are easy to find since they were used by many British manufacturers as well as Rootes. Ebay is the best source, especially the UK version, and expect to double your cost with shipping which is expensive. Buy a lot if possible, even if you end up with a couple of odd sizes left over. The Mk II 15/16 AF X 7/8 AF is also available, but most sellers know who needs it and it is usually more expensive than a basic spanner.

Pliers: The pliers are hard to find, so beware of the TW “Made in England” items with squared holes which are plentiful on Ebay but not correct for the Tiger. Look for a round opening for the wire- cutter feature and the small “Made in Sheffield England” lettering around the pivot. The shape and style are very distinctive as shown in the pictures, and quite different to most, if not all, of the pliers in other non-Tiger/Alpine kits.

Screwdriver: Also hard to find; look for the round shank and a slightly tapered ferrule blending into the wood handle. Many other screwdrivers out there have a flat section where the shank enters the handle.

King Dick Spanner: Easy to find, but they come in 2″, 4″, and 6″ lengths. You need the 4″ version with “King Dick” stamped on the slider. Adjustable spanners with “Abingdon” stamped on the jaws are incorrect.

Nave Plate Extractors: These are usually available from Sunbeam Specialties under P/Ns VT53 and VT 54. (pdf)

Tire Valve Tool: This is available, at a price, from XKs Unlimited. They also have a metal version but we need the plastic part.

Lucas Distributor Key: If you decide you need this it is available from Moss and Moss Europe.

Tommy Bar and Sparking Plug Spanner: These items are very rare and seldom seen for sale. The few I have seen on Ebay were very expensive.

3D Printed Items Might be an Answer

To address this, we have been working on 3D printed items; the process involves reverse-engineering original parts to produce detailed drawings similar to what Rootes would have done in the ‘60s. These are then developed into 3D surfaced models in a format that the printers can read.

We had a company make black plastic replicas and steel reproduction parts. The metal parts are made by 3D printing a wax replica and using that to make a mold. The wax is melted out and metal is poured into the cavity (lost wax process), the mold is then broken away revealing the finished part. Additive manufacturing has some limitation in reproducing very small machined details, so we went through several prototypes developing the optimum look. For these reasons we have not attempted to replicate the spring loaded detents on the Tommy Bar.

The dimensionally-accurate parts shown below are plastic and the bare surface is rougher than the machined original; a little paint might improve the look.

These pieces can be place holders in your kit until you find original items. We did not make many because cost was more than people were prepared to pay.

For more information on repro tools or to provide more information on the subject of tool kits contact me at: www.motorsportmemories.com/contact

British/American Dictionary

Wheel Brace = Lug Wrench

Tyre Valve Key = Tire Valve Key

Spanner – Adjustable = Adjustable Wrench Spanner – Sparking Plug = Spark Plug Socket Tommy Bar = Spark Plug Socket Handle Spanner = Wrench

Nave Plate Extractor = Hub Cap Remover

Download a January 2021 updated and large pdf of this article

Comments (2)

Wow, what an excellent resource! Incredible research, descriptions, photos of the correct Tiger tool setup. Having spent a good deal of time sourcing the correct kit, I can attest that any serious Tiger owner will find this information invaluable.

Thank you,

Bruce Thatcher

1966 MkI

Great article. Thanks for taking the time to do it right and provide additional sources.