by Joe Parlanti

Restoration of the Alpine and Tiger Fuel gauges are relatively straightforward operations and can easily be performed by the amateur. The two gauges are identical in their operation so we’ll concentrate on the fuel gauge for this document. They are simple devices and restoration is generally just a matter of a thorough cleaning.

Here’s a “before” photo of the gauge from my 1966 Tiger. As you can see the everything is dirty and it has the typical faded needle.

Disassembly

The first task is to remove the stainless bezel. There may be a rubber O-ring behind the bezel that is easily removed with tweezers or a small pick. To remove the bezel, twist it until the 3 tabs line up with the corresponding slits in the gauge case. This may be difficult as the rubber gasket between the bezel and the glass has probably deteriorated to a brittle, hard, glue. I’ve found that using a rubber jar opener works great for getting the bezel to turn. Once the bezel is removed, you’ll need to get this stuff out of the part. You can sometimes chip it out but I found that soaking it in carburetor cleaner or similar solvent would loosen it up enough to get it out.

After the bezel is removed, the glass will come out easily.

Next remove the outer gauge face as shown here:

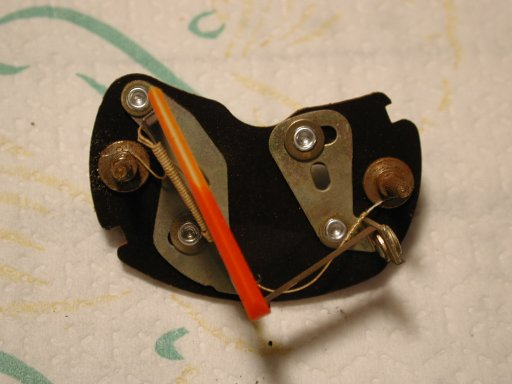

To remove the inner face, you’ll need to take it out at the same time as the movement itself. The needle is very fragile, so care must be taken to keep it from bending. Unscrew the 2 slotted barrel nuts on the back of the gauge and work the inner face out of the housing while holding it face down. This will allow the movement to fall free and be supported by the face with no load on the needle assembly. Once removed, gently slide the needle and movement out from the face. Here are photos of the inner face and movement:

Now that everything is apart it’s time to start cleaning, polishing, and painting.

Gauge faces

Clean them with a mild cleaner such as soap and water or glass cleaner. Test first on an area that won’t be seen for adverse reactions. The paint and silk-screened letters seem to be pretty durable though. The main area to be improved is the lower 1/3 of the gauge faces. Apparently, these gauges tend to fill up with water or moisture which collects there and leaves a stain. Washing as described above will get most of the dirt off but won’t restore the paint if it’s faded from UV exposure.

Glass

Wash with soapy water and then polish on a buffing wheel if desired. I find that buffing really get the glass clean.

Movement

Check first to make sure that the thin wire is still connected to both terminals. I haven’t checked with a meter but there is probably an optimal resistance that can be measured (if anyone has input, I’d appreciate it).

To paint the needle, I used an acrylic based paint found in most craft stores for about $1.50. The color I found that is the closest is Neon Red. This paint is very thick and must be thinned so as not to adversely affect the operation of the needle. Put a drop or 2 in a small container and add an equal amount of water. Brush a small amount onto the needle in a single stroke. One pass should be all that is needed.

Stainless Bezel

Use a buffing wheel with a stainless compound to polish the bezel. All but the worst parts will come out good as new.

Gauge housing

I used a brass wire brush on a wheel to clean up the case. It was originally cadmium plated and normally requires only a light cleaning. It could be painted if desired. The interior of the housing is painted in a light blue and hopefully will be in good shape. All of mine were. If not, locate the appropriate color and repaint.

Reassembly

It’s time to put everything back together. Here’s a photo of all of the parts:

Assembly is the reverse of the disassembly taking care once again with the movement and inner face. You’ll probably need to replace the O-rings. I purchased new ones from Barrie Robinson in Canada. He sells a complete set for the Tiger that consists of 14 O-rings (2 large & 4 small Jaeger’s gauges) for US$17 including postage.

That’s about it. Here’s a photo of the finished product. The whole operation does not take long and the results are very satisfying as you can see from the “after” picture shown below. Good luck.