by John Logan in the March 2008 RootesReview:

This article is meant to help answer the question, “Should I have my original 260 or 289 cid Tiger engine rebuilt or replace it with a 302 and will it fit?” Long time owners probably won’t find anything new here but many new owners have been asking the question. This is a discussion of, “What to consider” when making the decision rather than a detailed “How To”. If you are an absolute Tiger purest then you know the answer. If your 260 or 289 engine needs help, you will just have it rebuilt or replaced. However, if you are interested in having more performance, then a good used, rebuilt or new 302 long block engine may be a cheaper option and will be much better than a rebuilt and modified 260/289. Never consider having your block bored or stroked to make it a 302.

Will a 302 fit?

Yes, a 302 engine will fit without body modifications. The outside package dimensions of stock 302’s are the same as a 260 except for the five bolt rear face mounting pattern. All Tiger 289’s and 302’s have a 6 bolt pattern. The 302 requires a different flywheel, flywheel housing and front damper than the 260 and 289. The engine mounts, manifolds and front accessories will bolt to the engine in the same location but some changes are required to maintain the “V” belt drive.

What engine should I buy?

I recommend the 302 “roller cam” engines because they are much better than the earlier flat tappet engines. Therefore, I will mostly address their installation. If you enjoy rebuilding engines then your options are greater so your decision process will be different than what I’m going to discuss.

Level one, a used or junkyard engine

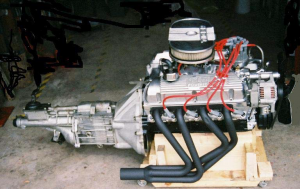

“Roller cam” engines were in production for over 10 years so good ones are still easy to find in junkyards. You can find an engine for sale at swap meets, in the classifieds or places like Craigslist, where I just found this ad;

Two 302 Engines – 1 Complete & 1 Partial – NEED GONE ASAP – HUSBAND OUT OF TOWN – $25

When shopping in a junkyard, you will find 302 “roller cam” engines in mid-1985 to 1995 Ford Motor Co. cars. The best are from a local low mileage car that is being parted out due to an accident. If an engine is still in the car, you can get some idea of its condition by the mileage, oil condition and the condition of the car. Obvious oil leaks and new gaskets could be evidence of recent problem.

When checking the engine at home, disassemble it as least as possible. However, if you want to gain confidence, pull the pan and check one crank and one rod bearing with Plastigage. The front cover will require replacement so take it off and check the timing chain for looseness. When you remove the intake manifold and valve covers, check for lifter and rocker problems. There usually won’t be problems unless there is a lot of sludge in the cam or rocker area. Don’t remove the heads. Just pull out the spark plugs to see if there is any sign of oil burning. Most all junkyards give some sort of guarantee so if things are worn out or the engine looks like it’s been worked on by some Vicegrip mechanic take it back and find another one. Expect to pay in the range of $200 to $800. The shape of the engine is not proportional to the cost.

Level two, a rebuilt engine

If you’re concerned about installing a used engine, you can find many engine rebuilders locally and in automotive buff magazines that can rebuild an engine to your specifications. If you buy a rebuilt engine from a performance shop with nonstock heads you may find that they require special intake and exhaust manifolds. This may lead to some expensive bodywork, so check that out before you buy. There are many horror stories about rebuild shops so plan on spending time asking around to find a good one. Expect to pay $1500 to $4000 depending on the extras. Again, the shape of the engine is not proportional to the cost.

Level three, a new high performance Ford crate engine

To eliminate the risk of a used engine or an unknown rebuilder, consider one of the factory new Ford Motorsports crate engines. The cheaper, iron head, long block engines Ford was selling are now gone but there may be some dealers that still have them in stock. A couple of samples of Ford Motorsports high performance 302 “roller cam” crate engines are listed below. Note that two of these engines have the “V” belt drive so they can be used in older cars. You can download the complete Ford performance catalog at www.fordracingparts.com or buy one for $5.00. Some Ford Motorsports dealers will give a 10% to 12% discount off the catalog.

| M-6007-EFM | M-6007-Z50Z | M-6007-X342 | |

|---|---|---|---|

| Displacement (ci) | 302 | 302 | 342 |

| Horsepower | 340 | 390 | N/A |

| Torque (ft-lb) | 310 | 360 | N/A |

| Compression Ratio | 9.0:1 | 10.0:1 | 10.0:1 |

| Heads | X303 GT-40 | Z304DA High Flow | X303 GT-40 |

| Crank | 3.00" Stroke Cast | 3.00" Stroke Cast | 3.40" Stroke Cast |

| Pistons | 4.000" Forged | 4.000" Forged | 4.000" Hyper-eutectic |

| Oil Pan | Production | Production | Production |

| Water Pump | Serpentine Belt | V-Belt | V-Belt |

| Cost (2008 $) | $4799 | $6199 | $5500 |

Modifications required to make it fit:

The accessory drive:

Your 289/260 flywheel and front damper can only be used in 302 engines built before 1980. They are intended for a 28.82 inch oz. external balance crank rather than the 50 inch oz external balance crank of all later engines. If you want your engine look like a 260, use the integral 260 front cover and water pump.

All 302 engines since 1979 use a serpentine accessory drive. Don’t use it unless you enjoy doing a lot of work relocating accessories and radiator connections. You must replace the front cover to convert from the serpentine drive to a “V” belt drive. If your engine has a “V” belt drive, you only need to modify the front cover.

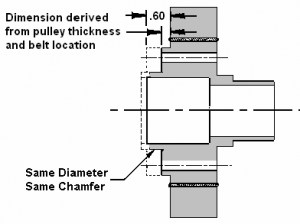

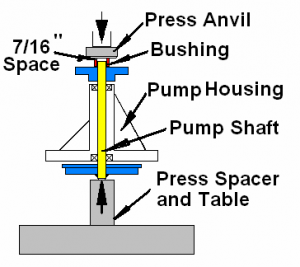

You will need to press back the pulley mounting hub of a new water pump about 7/16” to match the original Tiger location. I would recommend something like the Edelbrock aluminum water pump, which is lighter and has more flow. You can modify a 50 in/oz. damper as shown below, so that a thin drive pulley can be aligned with the stock water pump and generator pulleys. New dampers are available with three or four bolt holes for the pulley but used dampers will probably have four bolt holes. Three-hole pulleys can be converted to four holes and most all Ford pulleys will have the same center pilot hole. Multi “V” pulleys can be found in junkyards. If you find the right diameter in an assembly, you can take it apart by drilling out the spot welds. Correct 50 in/oz. dampers and front covers are available in junkyards at about a quarter if the cost of new ones.

You will need to press back the pulley mounting hub of a new water pump about 7/16” to match the original Tiger location. I would recommend something like the Edelbrock aluminum water pump, which is lighter and has more flow. You can modify a 50 in/oz. damper as shown below, so that a thin drive pulley can be aligned with the stock water pump and generator pulleys. New dampers are available with three or four bolt holes for the pulley but used dampers will probably have four bolt holes. Three-hole pulleys can be converted to four holes and most all Ford pulleys will have the same center pilot hole. Multi “V” pulleys can be found in junkyards. If you find the right diameter in an assembly, you can take it apart by drilling out the spot welds. Correct 50 in/oz. dampers and front covers are available in junkyards at about a quarter if the cost of new ones.

Starter:

You may use your old starter or the one with the engine but this might be a good time to replace it. There are several small geared and permanent magnet starters that are easier to install and lighter. They have their own relays so there is some simple rewiring required.

Heads:

The 302 “roller cam” heads will have four exhaust gas recirculation ports. They must be plugged. Ford Motorsports has special plugs with an internal and external thread. The thread is required on the front of the right head for the generator bracket.

Rocker covers:

Engines built since 1978 use wide stamped rocker arms instead of the narrow cast arms. If you are using rocker covers from your 260/289 you may have interference between the end rocker arms and the cover and its baffles. If the covers are the early cast ones you will have to replace them or do some creative welding rework. If necessary, you can move the baffles up closer to the cover surface but don’t run without them. They are there to keep oil from being sucked up through the PCV. You can use two cover gaskets or the thick rubber ones to raise the covers if you need more room. Check that you have rocker arm clearance before you install the engine.

Flywheel, clutch and bellhousing:

The original Ford Top Loader transmission will fit most aluminum housings intended for the Four-Speed. Housings are available at swap meets, junkyards and new ones are available at performance shops. You will have to find a six-bolt flywheel housing that fits a 57 tooth flywheel used by “roller cam” engines. Otherwise, the starter won’t mesh properly. Check that the transmission bolt patterns match the flywheel housing. There are narrow patterns, wide patterns and both patterns. You will need the narrow pattern or have a wide pattern housing modified by welding bosses inside and machining. You can use a Mark II clutch slave cylinder with an original or reproduction bracket.

Aluminum housings used with the T-5 Five-Speed look very much like the Toploader housings but they are too long and the pilot diameter is different. Also, the diaphragm type clutch pressure plate used with engines with the T-5 Five-Speed won’t fit inside the Toploader housing. Make sure the clutch pressure plate mounting pattern you plan to buy matches the holes and dowels in the flywheel.

Distributor:

If you plan on using your same distributor in a “roller cam” engine, you must replace the drive gear with one of different material. If you don’t, you will destroy the camshaft. These are recommended by Ford as follows:

Steel gears: M-12390-B (Color: None) are compatible with billet steel camshafts (hydraulic “roller cam” type).

Cast iron gears: M-12390-A (Color: Orange) are compatible with cast iron camshafts (hydraulic or solid flat tappet type).

Bronze gears: M-12390-C (Color: Bronze) can be used with either cast iron or billet steel camshafts. They are usually recommended by manufacturers of aftermarket billet steel solid “roller cam” camshafts but since the bronze is softer than cast iron or steel, they will wear at a faster rate.

The gears for EFI distributors have a 0.531”diameter hole for the shaft rather than 0.467” for point type distributors. The distributor should be “re-curved” to match the engine specifications. “Roller cam” engines have a firing order of 1-3-7-2-6-5-4-8. You may want to consider replacing the points with something like a Pertronix Ignitor #1281 or other electronic system. Make sure you have a distributor with vacuum advance unless you plan to do a lot of wide-open throttle racing or don’t mind buying more gasoline and want to live with added cooling problems.

Intake and exhaust manifolds:

If you want the new engine to look like the 260/289, then use the intake manifold, the Ford carburetor, exhaust manifolds and all the connections that go with it. There will of course be a reduction in the power potential of the extra displacement. I’m not sure how well the water jackets and gaskets line up but I think you can make it work. Used 302 “roller cam” engines are fuel injected so the intake manifold must be replaced. The light weight, aluminum Edelbrock Performer 2121 with a Holley carburetor is a good one and fits if you use a minimum of carburetor spacers. Don’t get one that is too high, like the Edelbrock RPM, or you will have to cut a hole in the hood. Use a carburetor rated at 600 CFM or less. You can use the original 260/289 iron exhaust manifolds or headers that are available from places like CAT or Sunbeam Specialties. I recommend that you have them Jet Hot coated with the silver/chrome finish to reduce under hood temperatures and increase their life.

Oil pan, pick-up tube and dip stick:

If the engine you find has a rear or double sump oil pan, you can replace it with your 260/289 oil pan and oil pick-up tube. If you buy a rebuild, specify the front sump. Ford crate engines have a proper front sump pan. You can use the 260/289 dipstick by drilling a hole in the front cover. There may be an impression in the casting to help you locate the hole but if not, use your old cover as a guide. Don’t forget to plug the dipstick hole in the block.

Cooling:

The larger displacement engine increases the cooling requirements. There have been many articles written about cooling so you should read them and then decide which ones make sense. Generally, you will have to upgrade the radiator and fan, plug up holes around the radiator and horns and add an air dam under the front cross member.

Oil filter and pump:

You can use the 260/289 oil filter set-up but this would be a good time to relocate it to improve air flow behind the radiator. The short filter elements screwed directly to the block are an easy solution. Others will disagree but these filters have less capacity. Since they have less pleat area, they have more restriction, and thereby reduce oil pressure. This can be overcome by replacing the element often and replacing the original oil pump with a high flow pump, especially if you are using a used engine. Unlike a high pressure pump, the high flow pump will increase the pressure at all speeds.

Miscellaneous items:

With a new intake, you will have to re-plumb your heater and find a place for the stock temperature sender. The Edelbrock Performer has a threaded port at the coolant outlet for the temperature sender but you will need an adapter with threads that match the original sender. There is a port at the rear of the intake manifold that works well for the heater inlet. The radiator hoses thermostat and oil pressure line are in the same areas. If you are using a new carburetor you will have to work out the fuel line and the linkage for the throttle and choke.