By Joe Parlanti

(Originally published as two articles in the Rootes Review – Vol. 33, No. 5, May 2007 and Vol 33, No. 6, June 2007)

Most of us with original wood steering wheels are aware of the issues attributable to age and exposure to the elements. Some people prefer a more modern aftermarket wheel, but I like the look and originality of the original steering wheel, so I decided to restore mine.

This article will outline the restoration procedures for the steering wheel itself, horn ring, and steering column covers.

Steering Wheel

There are 2 distinct tasks involved with restoring the steering wheel.

- The first deals with the wood itself which over time can become loose and separate from the inner steel rim. My wheel had apparently been restored at some point in time, and was not too bad, although there were some loose sections.

- The wheel rim is made up of several pieces dovetailed together around a round cross section core. Initially, I had intended to just re-glue the loose pieces and then deal with the cracked plastic hub.

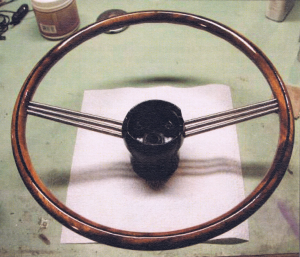

As you can see from these photos this was going to be a big effort with questionable results:

I had another steering wheel which was missing the wood that had a much better hub so I started looking at transferring the wood to it. Luckily, the glue had weakened to a point that with a little persuasion, the rim came off in four pieces.

I had another steering wheel which was missing the wood that had a much better hub so I started looking at transferring the wood to it. Luckily, the glue had weakened to a point that with a little persuasion, the rim came off in four pieces.

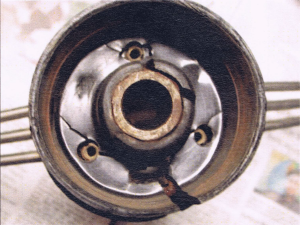

I cleaned the inner steel rim of all glue and other material and began to test fit the wood pieces. It did take a little filing of the brazing around the spokes and slight carving of the groove in the wood to provide a perfect fit.

I used a standard model aircraft epoxy to attach the wood to the rim. All I had was the 5 minute stuff which didn’t leave much working time. It would have been much easier with 45 minute epoxy. I held the wood pieces together with standard wood clamps.

To this point, I had not done anything to remove the existing finish on the wheel because the wood pieces are quite fragile when not bonded to the rim. I tried sanding but the going was difficult so I switched to a chemical stripper that was safe for wood. No real magic here but be very careful to keep the chemical off of the plastic insert embedded in the face of the wheel. It is susceptible to dissolving by the stripping chemicals.

To this point, I had not done anything to remove the existing finish on the wheel because the wood pieces are quite fragile when not bonded to the rim. I tried sanding but the going was difficult so I switched to a chemical stripper that was safe for wood. No real magic here but be very careful to keep the chemical off of the plastic insert embedded in the face of the wheel. It is susceptible to dissolving by the stripping chemicals.

Once all of the old finish is completely removed, sanding is necessary to prepare the wheel for the new finish. I was very careful to remove only as much material as was needed to smooth everything out, progressing to finer grits of paper.

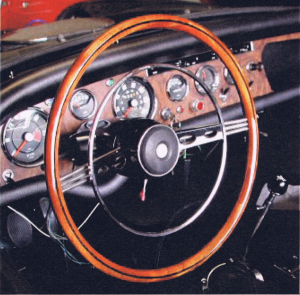

The finish applied is up to the individual tastes of the restorer. Some people like a darker wheel which requires a stain. I prefer the look of the natural mahogany and used a clear gloss polyurethane. It did darken the wood a fair amount but I was really pleased with the final look. I applied four to five coats to build up the finish. I then let the wheel sit for a day or so before sanding the finish smooth, progressing to finer grits of paper. I then applied several more coats.

Now that the wood is finished we can concentrate on the hub of the wheel.

Now that the wood is finished we can concentrate on the hub of the wheel.

Cracked Hub

It is almost a given that any steering wheel you attempt to restore will have a cracked hub, unless of course it has been previously repaired.

The material looks to be some sort of thermosetting plastic and very susceptible to damage by temperature extremes. The only way I’m aware of to correct the problem is to fill the cracks and refinish the hub.

Eastwood sells a series of steering wheel restoration kits which can include an epoxy based putty, an aerosol Pre painting prep, and an adhesion promoter. These kits range in price from S25 to S40 depending on the included items. I’m a big fan of Eastwood and their products, but after talking to Larry Paulick about the restoration of his steering wheel, I was convinced that it would not be money well spent. The epoxy putty that Eastwood uses in their kits is called PC-7. It is a peanut butter consistency 2-part adhesive that can be purchased at your local Ace or Tru-Value hardware store.

- Mix equal parts of the epoxy together and apply with a Popsicle stick to the cracked areas.

- After it hardens, sand it smooth with coarse grit sandpaper.

Since the hub has been distorted by the cracks, there’s really no way to get it back to its original shape without extensive work, so it will probably not look like a new one ever again. The best we can do get it as close as we can. Luckily, most of the hub is hidden.

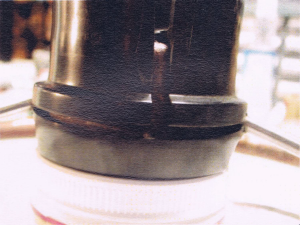

I used an automotive glazing putty to fill the imperfections sanding, filling, and priming until I was satisfied with the result:

I used a gloss black enamel paint from the hardware store an then applied a UV resistant clear coat to add more gloss.

One final note.

This same procedure can be used to fix cracks in the rim of the non-wood Alpine steering wheels.

Restoration of the horn ring can be an easy task depending upon its condition. The horn ring is a pot metal piece that may be cracked or broken in the center, be pitted under the chrome or the black paint on the spokes may be rough.

If your horn ring is cracked, the best solution is to purchase a new one from Rick at Sunbeam Specialties. It is supposed to be stronger and better made than the original. I have repaired cracked horn rings in the past, but it is difficult to do.

My horn ring was in fairly good shape with minimal pitting, so I just polished the chrome with a buffing wheel. The black paint was also in good shape and I was able to polish it without having to repaint. Repainting is straightforward; just mask the wheel and go. On one of my other cars I powder coated this part which also worked well.

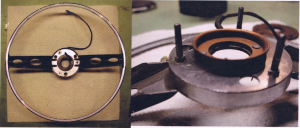

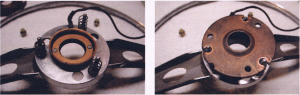

The last part of the restoration is cleaning the horn contacts.

These can become oxidized and dirty over time which will prevent the horn from working properly. This mechanism basically consists of 2 copper plated components which when brought together, complete the circuit and energize the horns. There are 3 studs embedded in the horn ring which fit through springs and an insulating nut or bushing which hold the top piece in place.

The only thing to do at this point is to clean all of the parts, especially the copper plated ones.

I used my buffing wheel for the copper parts, but please note, the plating is very thin and can be removed easily if you get overzealous with the buffing wheel.

Reassemble the horn ring contacts, checking with an ohm meter that there is no continuity between the top copper plate and the copper cup attached to the horn ring.

Adjust the gap between these 2 pieces until about 1/32″ by tightening the 3 nuts. Make sure the gap is even all the way around the contactor.

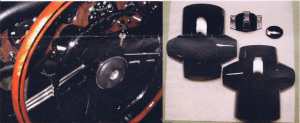

The steering column pieces can be restored in 2 ways.

You can polish them which will leave a brownish patina finish, or you can paint them as I did. The pieces are made of Bakelite which as I found out has oils embedded in the material that can still surface after 40+ years to wreak havoc with your finish.

After making a mess in my first attempt, I consulted the experts on the Tiger list and received the following procedure:

- Clean the parts thoroughly with soap and water.

- Use a Scotch-Brite pad to roughen the surfaces to be painted.

- Clean the parts with an automotive paint prep which removes all of the oils, silicones, and other impurities.

- Repeat steps 2 and 3 at least 1 more time, being careful not to touch the parts with your bare hands.

- Lay on the first couple coats of paint very lightly, almost as a mist, to give the subsequent coats a painted surface to adhere to.

- Apply another coat or 2 until you’re satisfied with the finish.

Now that all of the parts are restored, you can put everything back together and onto the car. As with most of the things I’ve restored on my car, I learned a few new things, talked with a few new folks, and completed a most rewarding job that, by the way, looks great!

Thanks, Joe, for a most informative article. This will be a good one for those winter nights when the car is out of service till spring, at least for us Northern residents! Ed.