by Rob Guerra in the February 1996 RootesReview

Like most Tiger owners I have always wanted my car to perform at its peak without too much crazy modification. What to do about wheel hop, cornering, acceleration? How do I make my car perform better on the track? Well I was relatively confused. I knew the Tiger came with a Panhard rod, but what about traction masters? What does all this stuff really do? Here is an article I found and paraphrased from the September 94 Car Craft magazine.

A beam (solid or non independent) rear axle must be kept properly located and loaded in relation to the chassis both laterally and longitudinally under various vehicle dynamic conditions. In contrast to coil springs, leaf springs (like those in your Tiger) inherently provide some lateral and longitudinal location, but at high g loads, they need help.

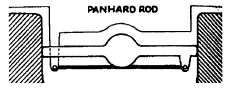

Panhard Rod

For lateral (side-to-side) location, you have the choice of either a Panhard rod or Watts link. The simple Panhard rod consists of a tube with a pivot (elastomer bushings or spherical rod ends) at each end that attaches to the chassis on one side of the car and the axle at the other, thereby constraining lateral axle movement. Assuming no structural deflection, the rod restricts lateral axle movement to the horizontal component of an arc described by the end attached the axle as it swings. Thus, the longer the rod, the more effective its control–but a long rod must go around the differential, requiring extended (and hence very strong and stiff) bracketry. Likewise, designing the Panhard rod so it parallels the axle at vehicle ride height (with -the driver and half a tank of gas) also helps maximize lateral control, plus it keeps the roll center height as constant as possible.

The roll center location rod is the intersection of the rod with vehicle centerline. Generally, a lower rear roll center aids consistent handling, so try to mount the bar as low as possible. The roll center will change as the vehicle rolls and the Panhard rod swings in its arc with the amount of change varying depending on whether the vehicle is turning right or left. By anchoring rod to the chassis left side and the axles right side, the roll, center rises as the chassis rolls to the right during left hand turns (and vice versa). This causes more load transfer to the right rear tire when accelerating out of a left turn, than it would when accelerating out of a right turn, and it helps counteract the right rear tires tendency to lift during hard straight line acceleration.

The roll center location rod is the intersection of the rod with vehicle centerline. Generally, a lower rear roll center aids consistent handling, so try to mount the bar as low as possible. The roll center will change as the vehicle rolls and the Panhard rod swings in its arc with the amount of change varying depending on whether the vehicle is turning right or left. By anchoring rod to the chassis left side and the axles right side, the roll, center rises as the chassis rolls to the right during left hand turns (and vice versa). This causes more load transfer to the right rear tire when accelerating out of a left turn, than it would when accelerating out of a right turn, and it helps counteract the right rear tires tendency to lift during hard straight line acceleration.

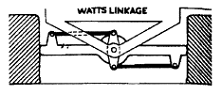

Watts Linkage

Because it offers symmetrical lateral axle location and a fixed roll center at the main link pivot, the Watts link is generally considered superior to the Panhard rod, but it’s harder to fabricate. You must attach the pivot to the chassis (not the axle) and both links must parallel to each other and the ground at ride height. It is harder to change the roll center because the whole mechanism must be relocated. The brackets must be extremely strong to absorb lateral loads which could peak as high as 10,000 pounds.

Every lateral stability device has a roll center. On an ordinary leaf-spring suspension, it’s the front spring eyes. But when using a Panhard bar or Watts link as the primary lateral control mechanism the original spring eye roll center tries to “fight” the new roll center provided by these devices. Minimize friction by using spherical bearings in the spring eyes in place of the stock rubber bushings. This also aids longitudinal location during hard acceleration.

Every lateral stability device has a roll center. On an ordinary leaf-spring suspension, it’s the front spring eyes. But when using a Panhard bar or Watts link as the primary lateral control mechanism the original spring eye roll center tries to “fight” the new roll center provided by these devices. Minimize friction by using spherical bearings in the spring eyes in place of the stock rubber bushings. This also aids longitudinal location during hard acceleration.

Traction Bar

But hard accelerating Tigers often need even more longitudinal control. The traditional hot rod straight line solution is a traction bar. However, under cornering conditions or when autocrossing, the traction bar and leaf spring fight each other, causing axle hop. A simple solution for a handling car is to fabricate clamps for the leaves forward of the axle, so that this portion of the spring serves only as a locating device, leaving most of the springing action to the rear portion. This makes the front portion of the spring into an effective trailing arm, and works just fine as a locator without causing tramp due to the release of energy or hopping due to geometric binding.

Torque Arm

In the past torque arms have generally not been used on leaf spring suspensions. However, unlike a traditional set of traction bars clamped to the leaf springs, such a “single-center” device provides longitudinal control with minimal adverse effect in roll by controlling only the pinion angle. According some literature, torque arms are more effective when mounted to the right of the driveshaft. Adding a torque arm to a leaf-spring car is a new development, not yet covered in most available literature. It is my understanding that new member Dan Walters has manufactured a torque arm specifically for the Tiger. If you’re interested, write to Dan at P.O. Box 11771, San Bernadino, Ca. 92423-1171