by Ron Fraser in the October 2006 RootesReview:

The oil pressure switch to activate the fuel pump is definitely one good way to address the problem of a fuel pump continuing to run after an accident.

Today’s vehicles all use an inertia fuel shutoff switch to shut the fuel pump off in an accident. Inertia switches are readily available; they can be bought new or used. The inertia switch is generally mounted in the trunk area with easy access and near the fuel pump. The switch is then wired in series to the pump.

I have seen manufacturers’ wiring diagrams that place the switch on the ground side of the pump and on the 12v feed side of the pump. I vote for locating it on the 12v feed side of the pump; that way there is no chance the pump will find a ground after an accident and start pumping again.

Possibly the ideal system will incorporate an oil pressure switch to a relay to the inertia switch to the fuel pump. The oil pressure switch would shut the pump off if the oil pressure drops off. The Inertia switch will shut the pump off in case of an accident.

and from John Logan in the October 2006 RootesReview:

I have an inertia switch on my Cobra that I got in a junkyard for $3.00 and wired into the hot lead. If it were also wired into the oil pressure switch of a Tiger it would need a complicated circuit of relays so the pump would start running as soon as the ignition was turned on. It would not be advantageous to have it on only after turning the switch to the start position, since if the car has been sitting for a long time it would take too long to fill the bowls. Also, there needs to be a way to run the pump when doing fuel system work.

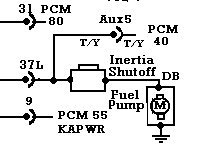

Below is a section of my wiring diagram of the Cobra where the input goes to the computer. The computer starts the pump to pressurize the fuel injectors and then shuts it off until the engine senses engine rotation. Tigers, of course, don’t have computers.