by Fred Mistr and Tom Ehrhart

The December 1981 newsletter (Vol. 6, No. 9) contained an article about that dreaded Alpine disease LOP, or low oil pressure. In that newsletter, Sunbeamites were coached on how to nurse your engine back to a healthy life. One area not covered in that Tech Tip was how to massage its heart (the oil pump) back to life.

This Tech Tip is the next best thing to a pacemaker for your Alpine, and a whole lot cheaper, too! In fact, you will save so much money from this tip that you will be able to renew your Tiger East/Alpines East membership for about five years!

As mentioned in the December newsletter, there are basically three major causes of Alpine LOP: 1) Excessive rod, main and cam bearing clearance; 2) a defective oil pressure relief valve; and 3) the oil pump, the subject of this Tech Tip.

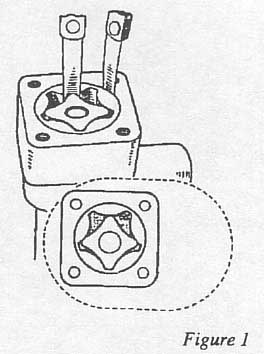

Now that the engine bearings and relief valve all have been renovated properly, let’s get into the oil pump. The pump wears out in two areas 1) the rotor tips and outer rotors, as shown in Figure 1, the rotor and housing, causing excessive end play (Figure 2).

There are no remedies commonly available to the owner for worn rotors. However, we do have a way for everyone to eliminate rotor endplay, which is the area needing the most attention. As the pump is used, the rotor will wear out the inside of the housing, allowing more than the acceptable amount of 0.001″ to 0.003″ end play (see Figure 2 for measurement). Since the excessive gap is really between the housing and rotor, it is a simple matter of removing material from the housing in order to bring the gap back into specification.

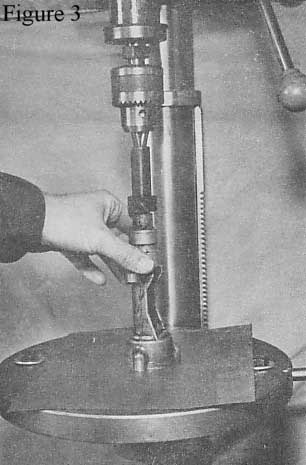

This process is accomplished by using a piece of #400 wet/dry sandpaper placed on a very flat surface! Place a thoroughly cleaned pump on top of the sandpaper and hold against the paper by firmly pressing down on the rotor shaft. A drill press works nicely for this operation (see Figure 3). However, with a little care, you may do it with only your hands.

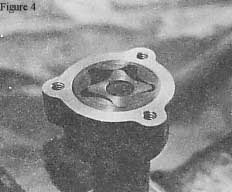

With the pump held in position firmly by the rotor you will notice the housing turns very freely. This is the critical operation stage. While rotating the housing lightly against the paper, you will obviously be removing material. It’s aluminum so it won’t take much effort to remove the material. Check the gap frequently until you are down to 0.001″ to 0.003″. Shoot for 0.001″, since that will obviously give better oil pump efficiency. The finished product should look like that shown in Figure 4.

Remember to thoroughly remove all grit resulting from this procedure before re-installing! If you wouldn’t eat off of it ? it’s not clean enough.

With the oil pump rotor end play held in check, you have greatly enhanced its efficiency. You now have a NEW Alpine engine.