Wow, it’s been twenty years since I first worked on this alternator conversion. I’ve had no problems with since then. But recently I have received some questions. So I thought it’s time to revisit and update the story. Twenty years ago I had a low-quality digital camera plus I wanted to look and see if anything else needed attention.

History of an Alternator Conversion

When I drove to SUNI at Big Sky, Montana, July 1999, I spent a week just being a tourist. Meandering my way west, stopping at National Parks, tourist attractions, sightseeing and more. I had an absolutely great time with zero problems from the generator charging system. Just a great drive adventure!

Driving home was another story. I had to stop several times to play with the voltage regulator points to restore the charging system. That was the last straw for the generator charging system on my Tiger. It was time to really think through the total process of how convert to an alternator charging system.

The easy parts

The majority of this system conversion was simple, buy parts, install parts. My difficulty was with the wiring harness and making it all work together. I read all the alternator conversion articles available at the time. All, IMHO, left the wire harness a bit of a mess. There had to be a better way.

One day after pondering this problem for hours, it struck me – CAN I MAKE THE VOLTAGE REGULATOR INTO A JUNCTION A BOX? Call this a eureka moment if you like but that idea launched me into action and into writing a Tiger engine alternator for dummies conversion article. Yes, I’m electrically challenged.

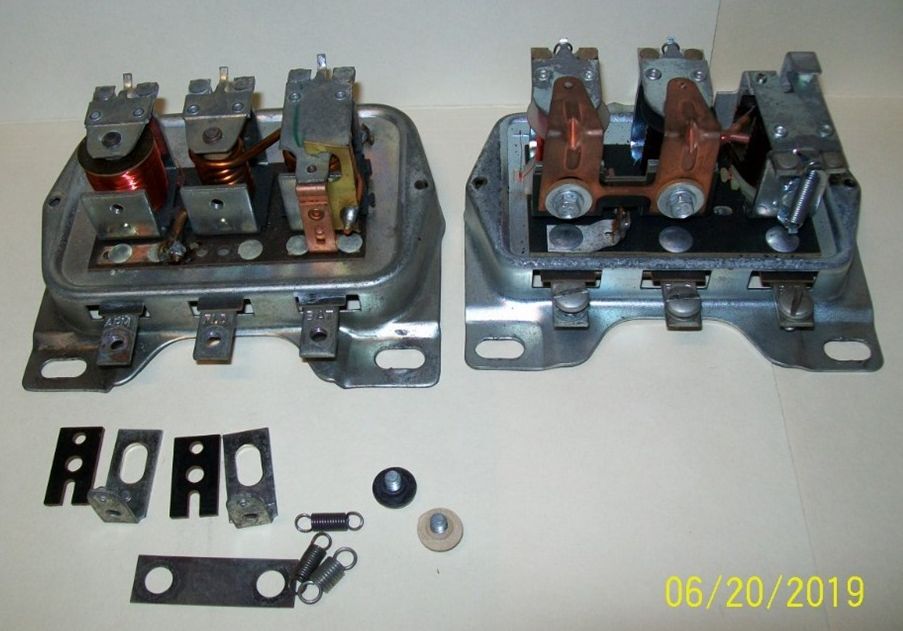

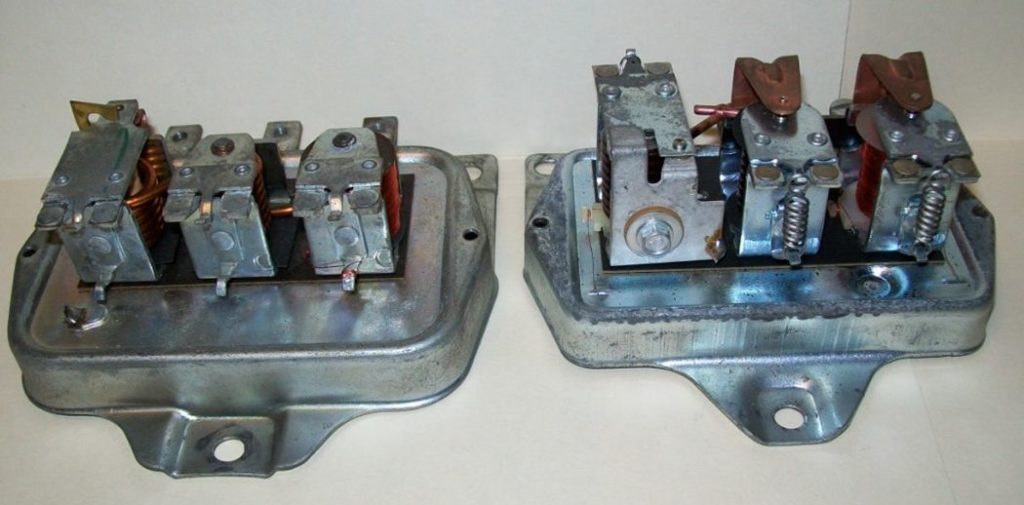

The main goal here is to disable your stock voltage regulator and turn it into a Junction Box so you can neatly attach the wire harness. I don’t recall making any other modifications to the VR but maybe necessary.

The objective is to have continuity between the two outer posts, armature and battery posts with the center post, the field post, isolated. This is now a Junction Box.

Note:

1. This Alternator bracket only works with a 60’s style Autolite Alternator; any other style alternator will require a different bracket design or modification of this bracket design.

2. The oil dip stick tube will need to be bent slightly and repositioned.

3. Be sure the pulley alignment is less than 1/8” – adjust position of the Alternator if needed better pulley alignment = fewer problems = longer belt life – VERY IMPORTANT

4. The fuel line bracket below the filter is where I believe the C3OZ-9180-A fuel line bracket listed in the Tiger Parts List – Petrol System – pg. UF1 was placed. I have never seen this bracket on any Tiger, possibly this bracket was deleted. The bracket does stabilize the fuel line very nicely.

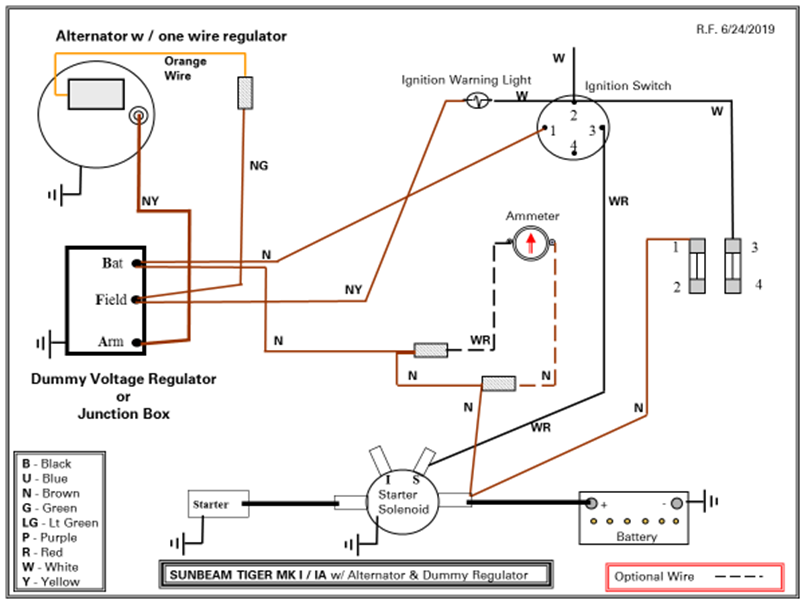

Wire Diagram:

Ford labels the VR posts as – Armature – the left post, Field is center and Battery the right post

The Sunbeam Tiger Shop Manual wire diagram lists D for Dynamo, F for Field, B for Battery but in Section N, pg. 14, the Ford notation is illustrated. Dynamo – D = Armature – A

Notes:

3/1/13: I found an error in the wire diagram I drew dated 4/19/03 for the Alt conversion. The ammeter connection was wrong. I’m not the electrical guy so errors creep in on me. I updated the drawing and included more details; starter, starter relay, and made the relay look more realistic.

4/11/15: One wire regulator added to alternator case. Regulator wired per instructions. This voltage regulator is now available at National Parts Depot.

6/24/19: I made additional changes to better reflect the parts, their mounted orientation and label details. I prefer wire diagrams that label parts as they appear. This clarifies the wiring for me and I hope other electrically challenged dummies like me.

Junction Box – connection posts orientation changed to reflect the actual part

Starter Solenoid – connection posts added and labeled; S post connects to the ignition switch; I post connects to the ignition coil

Ground symbols added

(Ed Note: also see M27 – Tiger Alternator Conversion II)

(Ed. Note: see also M47 – Tiger Alternator Conversion I)