by Chris Barker

From the UK through the Sunbeam Alpine Owners Club

Originally printed in the Rootes Review 1/86

The stylists’ and customers’ desires for frameless door windows on convertible cars present the automotive engineer with a number of problems and life is made more difficult when the winding window has to fit both a hardtop and a well-engineered soft-top frame.

Fortunately, as with many aspects of its design, Rootes did a thorough job in designing the Alpine/Tiger doors so that they can be set up to work well and to minimize draughts and wind noise. This article attempts to explain how to do this.

Window winders are one of the Alpine’s/Tiger’s known weak points but I think that most failures result from overloading caused by maladjustment or lack of lubrication; are yours stiff to turn?

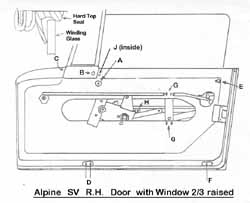

It’s worth mentioning that John Hayter of the Berkshire Sunbeam Alpine Center can supply reconditioned winders or kits of bits. Incidentally, the Rootes Alpine workshop manuals never mention these adjustments and the SV manual still has SI/II pictures and words for removing and replacing the winding window! Included is a sketch that will, I hope, help you understand the words. I have drawn a SV (of course!) but SIII and IV are very similar and some of the adjustments also apply to SI and II.

Before touching the door’s insides you should adjust the lock striker (on the rear wing front edge) and the hinge positions as necessary so that the door fits the body and closes easily. Unfortunately, there is no adjustment to compensate for worn hinges. The striker will lift the back of the door a little and shimming out the lower hinge might help but that will push the door back as well as up. Drifting out and re-pinning the hinges is the only long-term answer. Removal of the hinges usually requires an impact driver but sometimes a LARGE pozidriv (Allen) screwdriver and Mole grips (Vise Grips) are enough. If you have a hardtop, fit it. If not, raise the hood (top).

Before touching the door’s insides you should adjust the lock striker (on the rear wing front edge) and the hinge positions as necessary so that the door fits the body and closes easily. Unfortunately, there is no adjustment to compensate for worn hinges. The striker will lift the back of the door a little and shimming out the lower hinge might help but that will push the door back as well as up. Drifting out and re-pinning the hinges is the only long-term answer. Removal of the hinges usually requires an impact driver but sometimes a LARGE pozidriv (Allen) screwdriver and Mole grips (Vise Grips) are enough. If you have a hardtop, fit it. If not, raise the hood (top).

To get at the door innards you will, of course, have to remove the trim panel. Now, where do we start?

The first job is to set the top of the glass parallel to the hardtop edge rubber seal. Slackening the four screws “G” allows the rear of the winder to be raised or lowered, thus tilting the glass.

The next step is trickier. First a bit of explanation, the quarter light locates on the lower front window channel but it is fixed by a screw “B” (don’t lose the spacer behind the chrome if it’s a GT) and by the upper and outer screws at “C”. Remove these and you can pull the whole thing up and out but for adjustment, just slacken them.

The lower front channel is fixed by a screw “A” second screw “J” above and outboard of “A” inside the door on the other side of the channel and by two screws “D” at the bottom.

To undo “J” you need a 5/16 AF open ended or flat ring spanner. Screws “D” and “F” need a 5/16 AF socket, box spanner or cranked ring spanner. If all else fails drill out “D” or “P” with a 5/32″ drill and replace with pozidriv-headed self tappers. If “J” is stuck you won’t be able to remove the channel but adjustment should be possible.

Slacking “A” and “J” allows the top of the lower channel to move fore/aft to locate with the quarter light. The main adjustment is at the bottom of the channel; loosening screws “D” allows it to be moved fore/aft and in and out, and the quarter light and channel tilt accordingly.

The fore/aft is easy. Just set the channel so that the quarter light fits snugly against the screen pillar seal. Here’s a word of caution if you have hard and soft tops. My hood pulls the screen back a little so don’t make it too tight with the steel roof.

The in/out setting should be such that when winding up the window, with the door closed, the glass just, BUT only just goes outside the “flip” of the seal-see scrap view (detail view) on the picture and Note 1 below.

When all is well, tighten screws A, B, C, D and J. O.K. so far? Good.

Now slacken screws “E” and “F’. This will allow the rear channel to move fore/aft at the top and both fore/aft and in-and-out at the bottom. Set it out so that the window winds easily and has about 1/8” fore/aft freedom. I have found that a silicone rubber lubricant spray helps the glass slide easily. The winder channel on the bottom of the glass should be greased. That’s why I suggested setting up with the hardtop, but you might wish to make some comparisons.

To finish, a few miscellaneous points which may be helpful and which I hope will make this the definitive article on Alpine/Tiger doors:

- The rear edge of the winding window can be moved out if necessary by putting a washer between the top of the channel and the door. The upper limit for winding the window is set by adjusting the stop in the winder channel (screw “H”, accessible with the window about 2/3 up). The idea is that the glass should be as high as possible while just brushing over the outer ridge of the hardtop seal when the door is shut with the window up-see scrap view. That’s just about it. If you have hard and soft tops, raise the hood and see how things fit. There is inevitably more noise with the hood, inner skin at screw “E”. Don’t overdo it or the winder will be overloaded by friction with the outer waist seal and your glass will get (more) scratched.

- An almost perfect replica of the outer waist seal can be had from Paul Beck, Vintage Supplies, High Street, Stalham, Norwich, NRI29BB. It’s Part No. 771. This seal is about 1/2″ too long and I suggest you cut the excess off the back. This means that many of the indentations for fixing clips match up. You have to cut the one for the front clip and extend a few others. This is easy with a Stanley knife. Similarly cut the seal around the quarter light rear pillar. Amongst alternative seals are those for the Talbot/Chrysler Sunbeam and I see that Alpine West Midlands offer one, Part No. RU5.

- I am told that Lynch Bros. of Accrington still have clips for the outer waist seal (2212159). If you are desperate they are easily made from thin steel. The dimensions are on the sketch.

- Austin Maxi (or 1800) door seals will fit Alpine/Tigers. If your scrap yard has a recent car, get one front door seal. If there are only old cars I suggest you get two rear door seals (they last longer) and select the best lengths

- The Furflex trim under the edge of the aluminum tread plate is easy to find new but if you’re at the breaker’s looking for Maxis keep an eye open for a Golf. They seem to rust like Alpine tail pipes and this trim is used on all the doors.

- If you have to weld new metal onto the bottom of your doors make sure that the oval access holes for screws “D” and “F’ are not filled up! If in the process you lose the channel which holds the door seal it can be replaced with a piece of suitable bright trim that is off the side of a Herald or one of the cheaper Imps for example. Glue and pop rivet it in place wrong way around.

- Landrover parts 395598/9 can replace the screen pillar seal with the metal insert. They are a bit bigger but O.K.

- The winding glass rear channel filler can be replaced by felt strip 1?3/8″ by 1/8″. The length is 16″. I am sure that new fillers can be found for the other channels which are 1/2″ wide does anyone have definite chapter and verse? (Rev. Llewrab perhaps)

- Making new Tourer door trims is very easy; use 1/4″ foam between the vinyl and the hardboard. Clips can come from a scrap Minx etc. or from Woolies, part no. 260 (Tel Market Deeping (0778) 347347.

Comments (1)

Sir, Having read your very comprehensive and informative article above. I stil am stuggling with a problem i have with my drivers side winding mechanism on my 1966 Series V Alpine. I turned tha toothed quadrant round (over) and lost the tension on the coiled spring. Bad mistake!! I fabricated a bollt with a slot in it for the spring but without success. I am having great difficulty in locating a replacement and would really appreciate any help that would enable me to solve my problem. Many thanks.

Regards Derek Hawthorne.